About The Tank Sampling Company

The Tank Sampling Company is based in Southern England offering sampling and testing services in a wide range of applications within the wastewater sector.

Our work varies from domestic customers running a small package sewage treatment plant – we will visit site over the first months after installation, then regular sampling to ensure the plant remains compliant and the final effluent is with the limits of consent.

We also work for medium and large companies supporting their Quality Auditing Process and Environmental Management Systems (ISO 14001) by regular sampling and testing of their trade effluent, visiting multiple sites across the country.

We pride ourselves on providing a first-class service to a rapidly growing customer base.

TSC provides an independent service – we have no ties to tank manufacturers, tankering companies or servicing companies.

Compliance and performance management of interceptors and package sewage treatment plants

How do you know when the plant treating your effluent is performing as designed and within water authority or Environment Agency discharge consent limits?

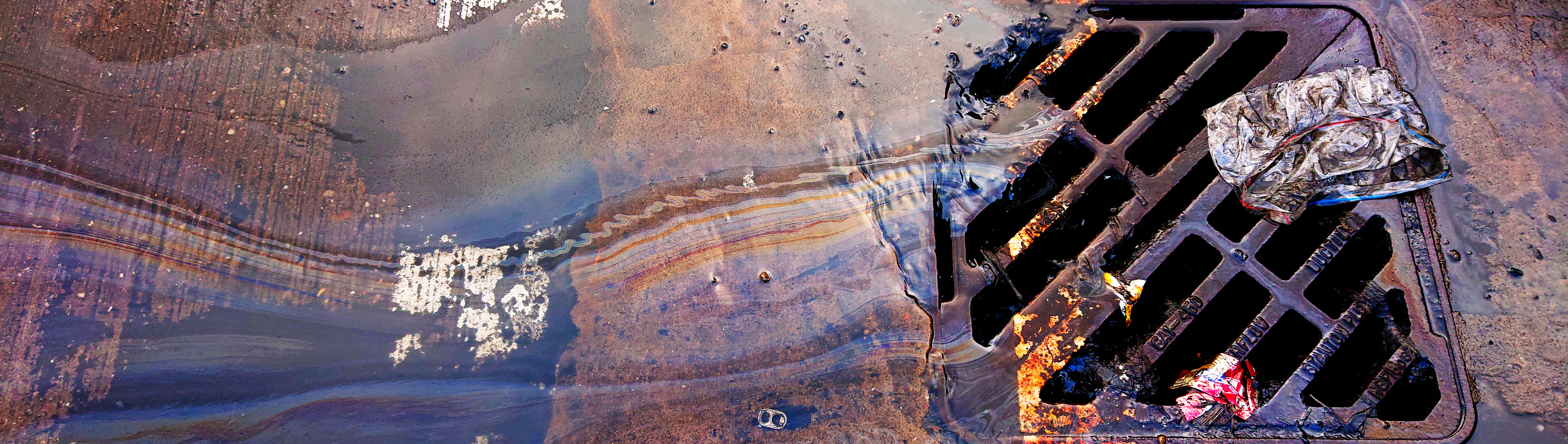

Oil and water separators, Petrol Interceptors, Package Sewage Treatment Plants all tend to be managed by regular emptying. But this does not determine whether the system is compliant.

Regular Sampling and testing, and emptying the tank when necessary can be a more effective method of managing these valuable assets.

Taking a sample and then analysing the substances and their concentrations as set down in the discharge consent document will confirm whether the final effluent is within the limits of the consent.

Emptying alone will not confirm whether the tank is performing as designed and is within consent.

Remain Compliant

When discharging treated effluent, it is the site owners’ responsibility to ensure their drainage systems are compliant and the final effluent in within the limits of the consent to discharge.

Monitoring of the final discharge through regular sampling and testing can confirm whether continued compliance is being achieved.

Sampling may find non-compliance, but upon finding an issue, the problem can be resolved quickly and efficiently.

Control Maintenance Costs

Many operators of interceptors (oil/water separators) maintain their treatment asset by routinely emptying the contents of the tank

Monitoring the oil and build volumes on a regular basis can prevent unnecessary clearances which generally result in expensive disposal costs. The sampling of the final effluent forms a part of the monitoring process which also determines that the tank is not polluting above permitted levels.

What we do

Monitoring the contents and final discharge from your tanks could reduce the maintenance costs by servicing them only when required.

Sampling and testing of the final discharge will also provide a record of the condition of the plant and it’s performance, enabling you to support any potential issues in the future.

What we sample and test

- Trade Consents

- Package Sewage Treatment Plants

- Oil/Water Separators / Petrol Interceptors

- Pump Stations

- Grease Traps

Where we sample and test

- Vehicle wash bays/Wash down areas

- Hotels/Pubs/Restaurants

- Petrol Forecourts/Refuelling Points

- Domestic and Commercial treatment plants

- Sensitive discharge within areas of SSI

- Schools and nursing homes

Email us for more information

We would welcome your enquiry about our services – Click this link to go to our ‘Contact Us’ page